At ATD Precision, we offer precision-machining services to local, national, and global customers across a wide range of industries. Our broad selection of machining capabilities and value-added services enables us to produce custom-machined components and assemblies to various specifications and standards. One of our core service offerings is multi-axis CNC turning.

Multi-Axis CNC Turning Centers

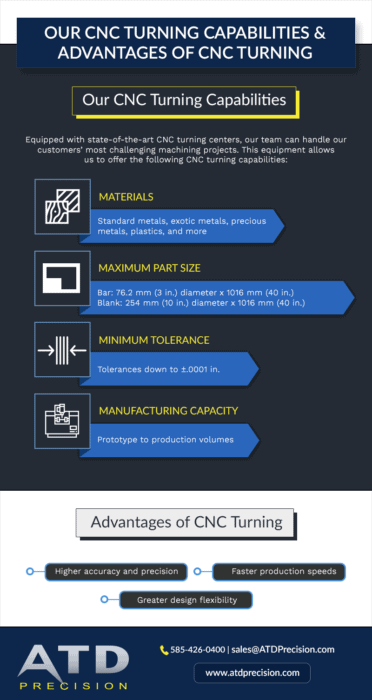

Our CNC Turning Capabilities

Equipped with state-of-the-art CNC turning centers, our team can handle our customers’ most challenging machining projects. These versatile work centers feature live tooling, double spindles, and multi-axis (up to five axes) capabilities, which enable us to turn and mill components in the same operation. They are also arranged in cells to maximize efficiency for parts requiring multiple sequences. Other equipment capabilities include large swing lathes, automatic bar feeders, tool life management, and machine vision cameras.

This equipment allows us to offer the following CNC turning capabilities:

- Materials: aluminum, steel, and stainless steel; exotic and precious metals; plastic polymers

- Maximum Part Size: from bar: 76.2 mm (3 in.) diameter x 1016 mm (40 in.); from blank: 254 mm (10 in.) diameter x 1016 mm (40 in.)

- Minimum Tolerance: ±.0001 in.

- Manufacturing Capacity: prototype to production volumes

Examples of typical CNC turned components include:

- Gears

- Knobs

- Pins

- Shafts

- Spacers

- Tubes

- Valves

- Other cylindrical parts with rotational symmetry

Ready to get started? Request a quote today!

What Is CNC Turning?

CNC turning is a subtractive manufacturing process that uses computer software to control the movement of the cutting tool and the rotation of the workpiece. During CNC turning operations, the workpiece is secured by a chuck and rotated, while the cutting tool is mounted on a slide or turret and fed toward it. As the tool moves across the surface of the workpiece, it removes material to achieve the desired shape and size.

Advantages of CNC Turning

Compared to other manufacturing methods, CNC turning offers several advantages, such as:

- Higher accuracy and precision. Since the CNC turning process uses computer software to control the operation of the manufacturing equipment, it is highly repeatable. As a result, CNC turned components generally meet extremely tight tolerances with little to no variation, even in orders of thousands of pieces.

- Faster production speeds. The use of computer software also allows CNC turning operations to be performed much faster than manual turning operations without sacrificing product or process quality, which means high-volume orders can be fulfilled in less time.

- Greater design flexibility. The CNC turning process can handle a variety of component designs when set up properly. For example, it can easily create asymmetrical features that would normally require additional sequences, which helps increase production speed and efficiency.

Partner With ATD Precision for Your Precision CNC Turning Needs

Looking for a partner for your next CNC turning project? Turn to the precision machining experts at ATD Precision! By choosing us, you benefit from our:

- Extensive experience. We’ve provided precision machining and manufacturing services for over 50 years. This experience gives us the knowledge and skills to produce highly challenging machined components.

- Vast manufacturing capabilities. We have a 45,000-square foot manufacturing facility that houses a multitude of advanced machining equipment, which provides us with the tools we need to create nearly any machined part or assembly our customers require.

- Broad range of services. In addition to our machining capabilities, we offer a variety of value-added services to ensure that our customers receive components that fully meet their specifications and standards. From machining to finishing to assembly, we can serve as a one-stop shop for all machined-component needs.

If you’re ready to get started on your project, request a quote today. We provide precision-machining services to local customers within the Rochester and greater New York area, as well as to customers across the United States and around the world.