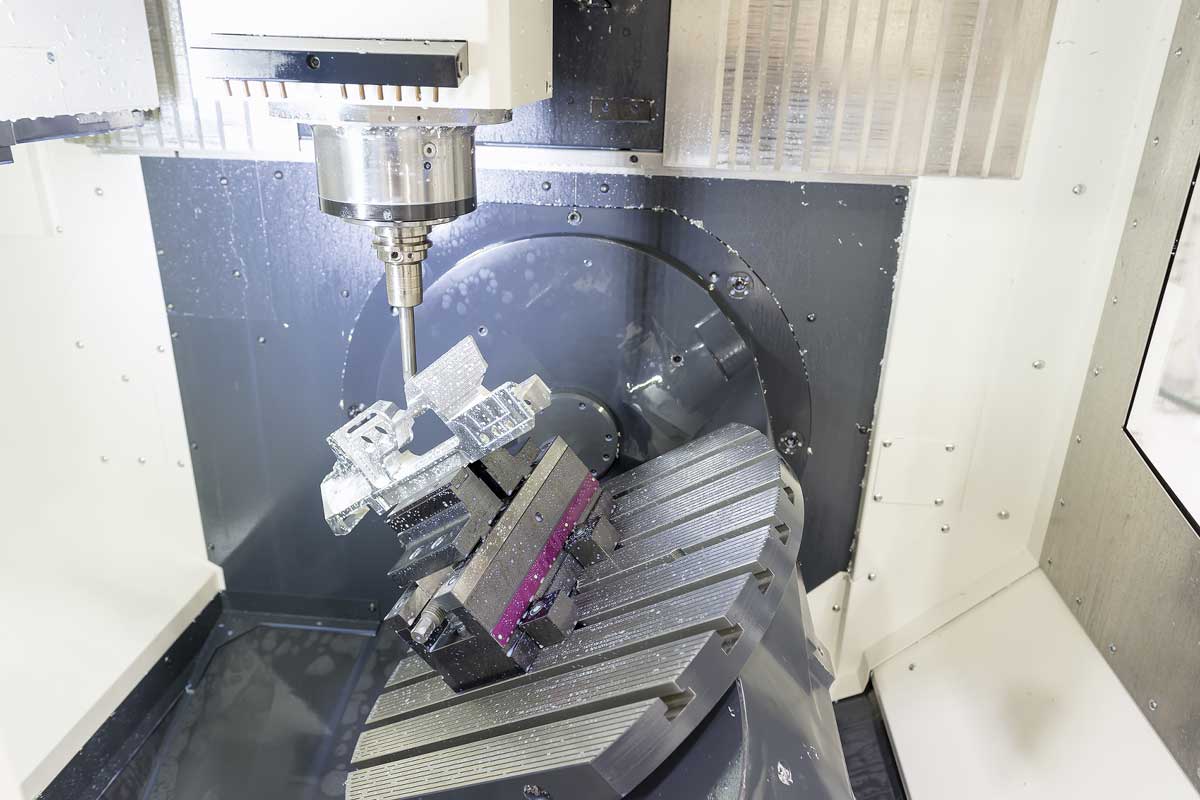

For over 50 years, ATD Precision has been providing precision machining services from our state-of-the-art facility in Rochester, NY. Our wide range of machining capabilities and value-added services allow us to deliver various custom–machined components and assemblies to several different industries worldwide. As part of our capabilities, we offer multi-axis CNC milling services. Our 3-, 4-, and 5-axis milling machines enable us to create ultraprecise and complex machined parts to meet the specific needs of our customers.

Multi-Axis CNC Milling Centers

Multi-Axis CNC Milling Capabilities

ATD Precision uses advanced horizontal and vertical CNC milling centers to manufacture precise, prismatic components with extremely close tolerances. Our machines are arranged in cells and are equipped with high-capacity tool changers and multiple pallets to maximize production efficiency. Our specific multi-axis CNC milling capabilities include:

- Close Tolerances. We can hold tolerances as close as 5 microns (0.0002’’) for feature of size and true positions of location as low as 13 microns (0.0005’’).

- Maximum Milled-Part Specifications. We can mill parts up to 510 mm (20’’) wide x 610 mm (24’’) high x 1016 mm (40’’) long.

Our high-precision CNC milling machines can operate on 3-5 axes simultaneously, with each multi-axis capability determining the type of milling and the kind of parts for which it is best suitable.

- 3-axis machining. With 3-axis machining, the cutting tool moves along 3 axes (X, Y, Z) to mill the part, moving back to front, up and down, and side to side. 3-axis machining is suitable for milling simple contours, surfaces, and slots. It is also sufficient for drilling, tapping, reaming, or boring holes.

- 4-axis machining. 4-axis machining performs the same functions as 3-axis machining but with an additional axis. 4-axis machining adds rotation around the Y-axis. Found on horizontal mills, this rotational axis allows a work-holding pallet to present multiple sides of a part or multiple parts to the cutting tool in the spindle. More complex features, such as spiral slots, can be created when using the 4 axes simultaneously

- 5-axis machining. 5-axis machining uses the same axes as 4-axis machining but with an additional rotational axis. This multiple rotational and axial movement allows for extreme versatility in positioning and contouring, making it ideal for creating intricate and complex parts for industries such as aerospace, transportation, medical, military, and fluid control.

At ATD Precision, we are pleased to offer multi-axis CNC milling for a broad range of materials, including standard metals, such as aluminum, steel, and stainless steels; exotic and precious metals; and plastic polymers. Out of these materials, we have manufactured a variety of precision–machined parts, such as:

- Castings

- Housings

- Manifolds

- Platens

- Plates

Ready to get started? Request a quote today!

What is CNC Machining?

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses a computer with pre-programmed instructions to direct the movements of tools and machinery. This process can be used on virtually all complex machinery such as mills, lathes, and grinders. With multi-axis CNC machining, the tools and workpiece move in three or more directions to remove material from the workpiece to create the desired part. This makes the production of complex, intricate parts quicker, more efficient, and more repeatable.

Advantages of Multi-Axis CNC Machining

Aside from added speed and efficiency, multi-axis CNC machining provides a host of advantages that makes it ideal for numerous industries. 5-axis CNC machining is especially beneficial, with key advantages such as:

- Ability to machine complex and intricate shapes with a single setup for enhanced productivity

- Lower fixture costs and less preparation time

- Increase throughput with shortened lead times

- Higher part accuracy

- Ability to use shorter cutting tools for decreased tool vibrations and higher cutting speeds

- Superior surface finishes and part quality

- Longer tool lifespan

Multi-Axis CNC Milling from ATD Precision

Multi-axis CNC milling is an excellent way to create highly precise components, regardless of design complexity. At ATD Precision, our multi-axis milling capabilities allow us to deliver extremely accurate parts with enhanced speed and productivity. Our 45,000 square-foot facility houses modern state-of-the-art equipment to ensure high-quality parts for customers in industries such as transportation, aerospace, medical, military, and fluid control.

Along with our multi-axis CNC milling capabilities, we offer other machining services such as CNC turning, Swiss turning, and precision grinding. We are also equipped to offer complex assembly and secondary, value-added services. We are proud to provide our precision machining services locally, nationally, and globally.

For more information about our multi-axis cnc milling capabilities, contact us today or request a quote to get started on your project.